1. Introduction

Ti-15V-3Cr-3Sn-3Al (Ti-15-3-3-3)

is one of the mostly widely used metastable Beta titanium alloys in aircraft

industries. A wide range of strength levels can be achieved by heat-treating

the Ti-15-3 alloy to meet various needs and applications. It has been reported

that a tensile strength over 1700 MPa can be obtained through thermo-mechanical

treatments of the Ti-15-3-3-3 alloy

Chinese Similar Materials: TB5 UNS

R58153

|

| Ti-15-3-3-3 Alloy Plate |

2. Chemical Composition

3.Physical Properties

1) Density:

4.77 g/cm3

2) Nonmagnetic

3)

Thermal Conductivity: 20℃ -- 6.1 100℃ -- 7.3 200℃ -- 8.8

300℃ -- 10.4 400℃ -- 12.0

500℃ -- 13.7 600℃ -- 15.4

300℃ -- 10.4 400℃ -- 12.0

500℃ -- 13.7 600℃ -- 15.4

4)

Specific

Heat Capacity: 20℃

-- 536 100℃ -- 551

200℃ -- 567 300℃ -- 583

400℃ -- 599 500℃ -- 616 600℃ -- 630

200℃ -- 567 300℃ -- 583

400℃ -- 599 500℃ -- 616 600℃ -- 630

5)

Electrical

Resistivity: 20℃ -- 1.45 100℃ -- 1.48 200℃ -- 1.51

300℃ -- 1.54 400℃ -- 1.57

500℃ -- 1.59 600℃ -- 1.60

300℃ -- 1.54 400℃ -- 1.57

500℃ -- 1.59 600℃ -- 1.60

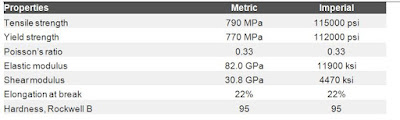

4. Mechanical Property

5. Other Designations

Equivalent

material to grade Ti 15V 3Cr 3Al 3Sn alloy is AMS 4914.

6. Fabrication and Heat Treatment

7. Machinability

Grade

Ti 15V 3Cr 3Al 3Sn alloy is hard to machine but can be successfully done using

slow speeds, high coolant flow, and high feed rates. Tooling should be

performed using tungsten carbide designations C1-C4 or cobalt type high speed

tools.

8. Forming

Grade

Ti 15V 3Cr 3Al 3Sn alloy can be hot or cold formed. Cold forming is easy to

perform. It is strip-producible.

|

| Ti-15-3-3-3 Alloy Bars |

9. Welding

Weldability

of grade Ti 15V 3Cr 3Al 3Sn alloy is rated as good.

10. Annealing

Full

annealing of this material can be performed by soaking at 792°C (1450°F) and

then air cooled. The material can be stress relieved at 538-649°C

(1000-1200°F).

11. Forging

Rough

forging can be performed at 982-1093°C (1800-2000°F) and completed at 816-927°C

(1500-1700°F).

12. Hot Working

Hot

working enhances the overall ductility of the material.

|

| UNS R58153 Bars |

13. Cold Working

Cold

working features of this material is same as that of a moderately tempered

austenitic stainless steel. Post-work annealing is recommended to re-attain

favorable performance properties.

14. Aging

Grade

Ti 15V 3Cr 3Al 3Sn alloy can be aged at 538°C (1000°F) for 8 h and air cooled.

15. Applications

Grade

Ti 15V 3Cr 3Al 3Sn alloy was primarily developed for airframe applications.

The

other application areas include:

l Aerospace fasteners

l Tubing and tankage

components

l Flat-rolled products

l Foil, plate, castings and

forgings.

|

| Ti-15-3-3-3 Hollow Bar |